Collaborative Engineering – The Technological Basis for the Digitalized Value Chain

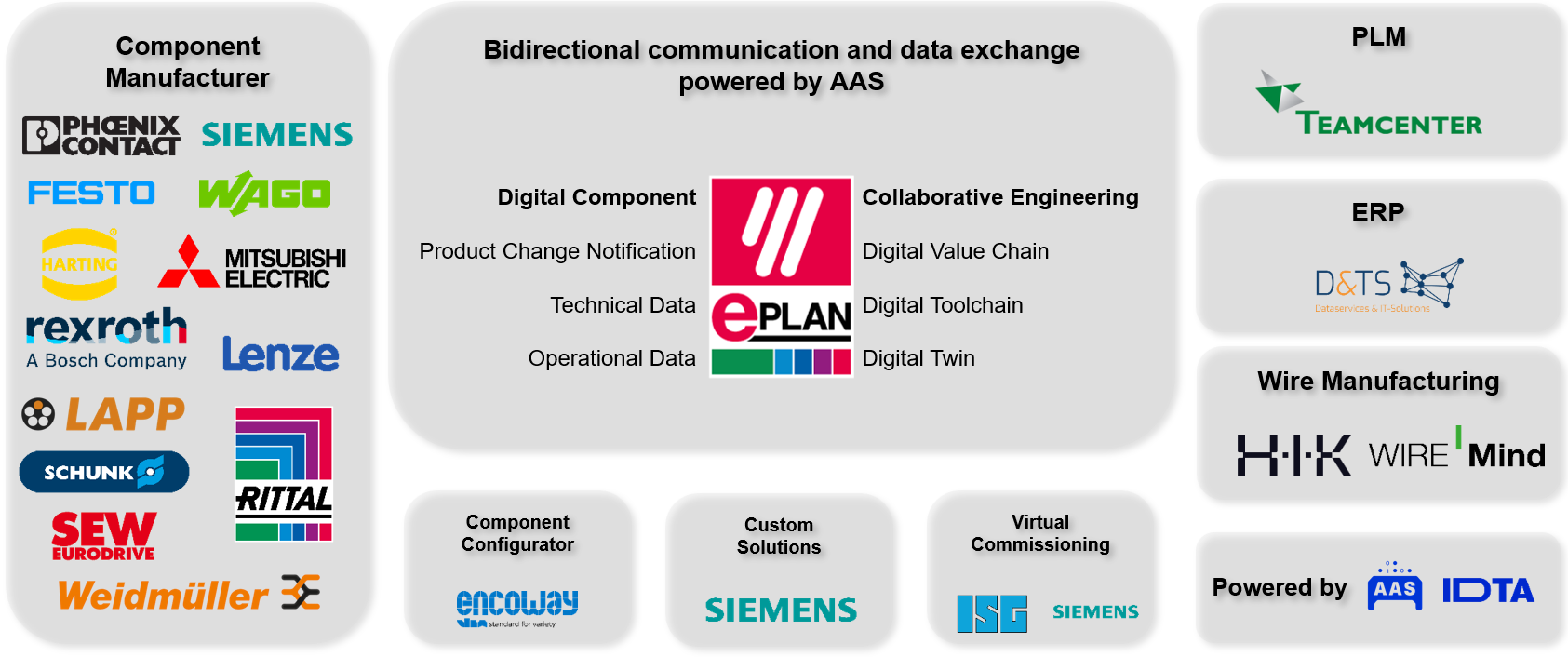

The Digital Twin of a machine is created in the software systems of all participating companies and uses the cloud for cross-system collaboration. It is crucial for the entire value chain and enables the automatic creation and processing of changes, such as product change notifications.

The Digital Twin in Engineering

Collaborative Engineering: Digital, Cross-system Collaboration in the Cloud

Digital Twins of components are already used in engineering to simulate, plan and commission a machine or system.

The provision of project information from different software systems as administration shells ensures consistent, standardized and synchronized development. The assignment of digital twins of the physical (instantiated) components makes it possible to provide the Digital Twin for the entire machine or system.

This guarantees seamless integration and interaction along the entire value chain. It also supports EU regulations and provides a way to record the carbon footprint.

Benefit of the Asset Administration Shell

- Consistent/standardized data throughout the entire life cycle

- Interoperable engineering systems

- Machine and plant documentation as a digital twin to fulfill EU DPP incl. Product Environment Footprint

- Embedded project change notifications to fulfill EU Data Act incl. EU Cyber Reslience Act

Collaboration Dashboard

Actively involved organizations

Used Submodels

Status: Prototype

WG meetings

Do you have questions or would you like to get further information about the Asset onboarding? Then write us a message.