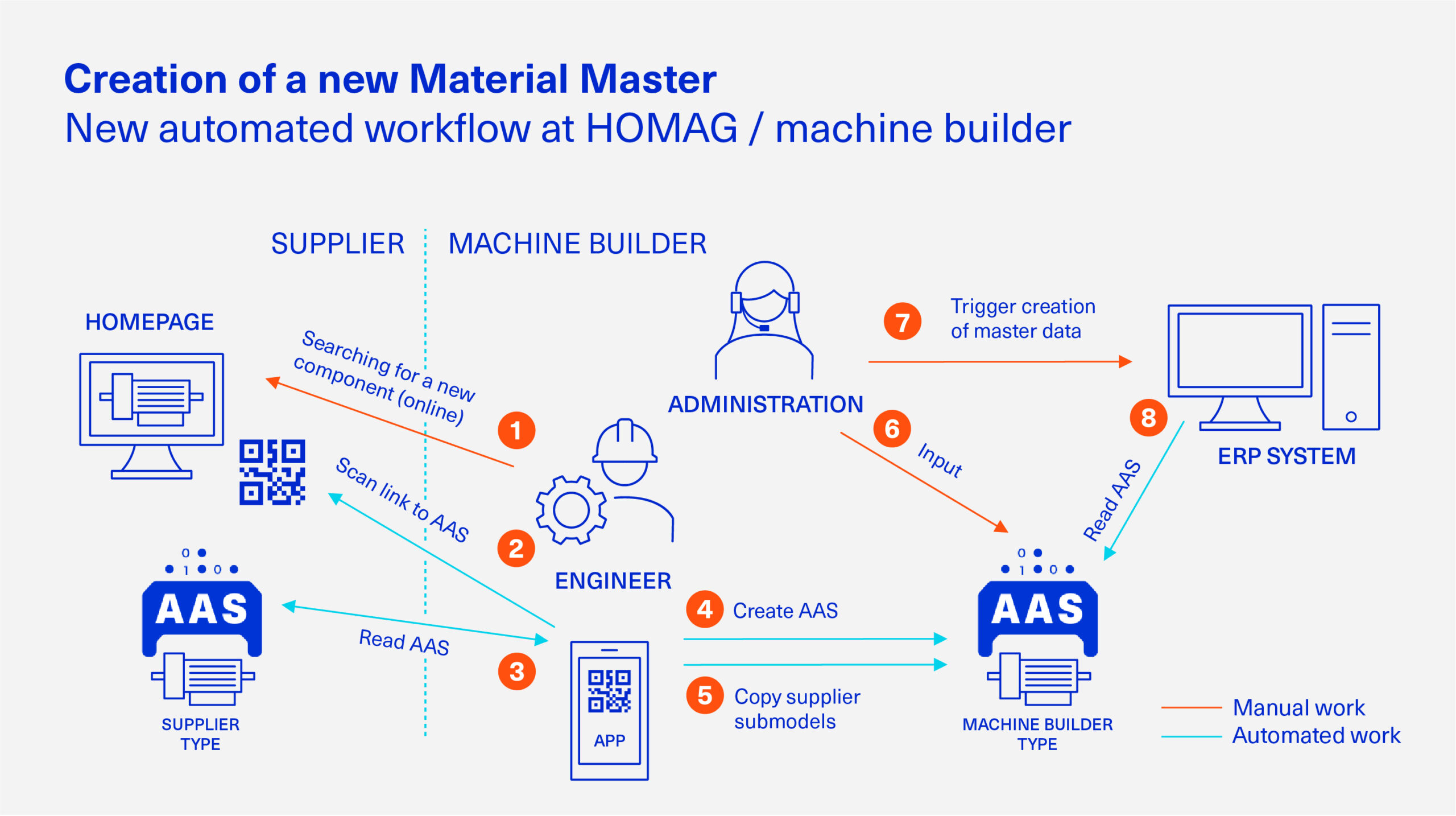

Automated Creation of Material Master Data – Full Interoperability

The material master for new components is created by direct transfer from the respective Asset Administration Shell instead of by manually entering values.

Improved data quality and data availability

Elimination of manual entry of material master data

When a machine builder uses a new component for the first time, a new material master must first be created in the ERP/PLM-system. This is usually a predominantly manual task today, because the necessary data has to be read from the component manufacturer’s documents and entered manually in the ERP/PLM system. The approach shown here, using the component’s Asset Administration Shell, eliminates this manual data entry.

Benefit of the Asset Administration Shell

- Standardised provision of component data by the manufacturer

- Direct data transfer to ERP/PLM system

- Perfect opportunity to become familiar with the AAS

Collaboration Dashboard

Actively involved organizations

Used Submodels

Status: Concept phase

WG meetings

Do you have questions or would you like to get further information about the Asset onboarding? Then write us a message.