Easy Access to Comprehensive Product Information thanks to the Standardized Digital Nameplate

IDTA standardizes machine-readable and multi-vendor specifications of the Asset Administration Shell

Industrial Digital Twin Association (IDTA) published the submodel “IDTA 02006-2-0 Digital Nameplate for Industrial Equipment” in October 2022. This standardized Digital Nameplate enables uniform and digital access to all important product information and allows users from the process industry and factory automation to attribute and exchange information about equipment in a value network. The submodel is an important element on the Asset Administration Shell. It defines uniform metadata within a digital nameplate and is based on existing norms, guidelines and standards. This paves the way for wide acceptance. The submodel can be used instantly and is available for the entire industry.

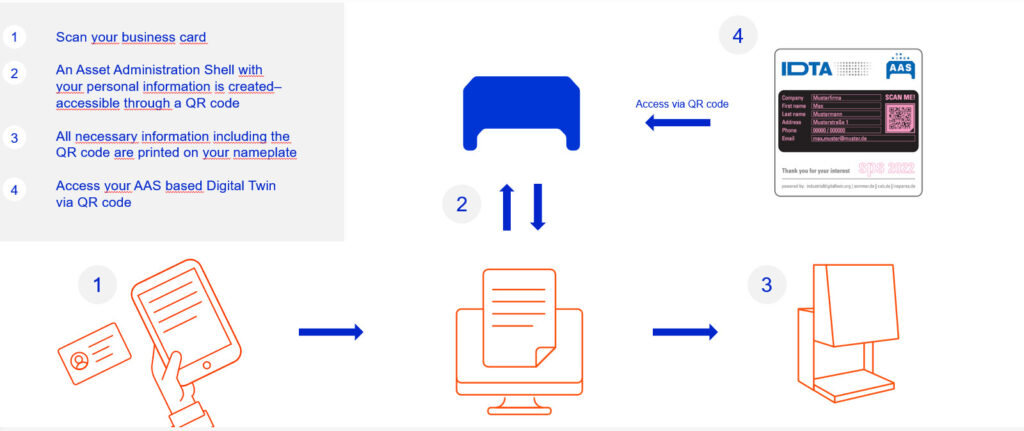

From providing high quantities of product data along the lifecycle, to increased flexibility in the event of changes to the product or software, to saving resources by eliminating paper documentation: The digital nameplate covers various use cases. Based on the digital nameplate, IDTA will show the demonstrator “Create your Digital Nameplate” at the trade fair SPS – Smart Production Solutions from November 8 to 10, 2022 in Nuremberg. By scanning an ordinary business card, a digital twin is created. Contact information is entered and clearly attributed. A QR code on an emitted physical nameplate grants access to the digital twin at any time. This implementation is based on IDTA standards and can be realized without requiring engineering effort.

The Standardized Digital Nameplate

The demonstrator of the company R. STAHL (more on the use case), a supplier of explosion-protected components and systems and member of IDTA, will also show at the SPS in hall 7 at booth 170 how Asset Administration Shells are efficiently applied. To access the standardized and digital information of a product, just scanning the corresponding code on the printed nameplate is required. Six real-life use cases illustrate the beneficial advantages of using standardized digital nameplates with Asset Administration Shells for existing and new equipment.

“In order to demonstrate the considerable advantages of the digital nameplate, we at R. STAHL have created a demonstrator for six real use cases. Based on our positive experience, we are currently in the implementation phase for the first series products. Together with other member companies of the IDTA, we have incorporated our expertise in the creation of the submodel. This standard enables the entire industry to implement the Asset Administration Shell in different machines and products and to apply it to their individual use cases. The interconnection of products with the Asset Administration Shell is more than just dry theory and is already happening,” says Roland Dunker, Digital Transformation Manager at R. STAHL.